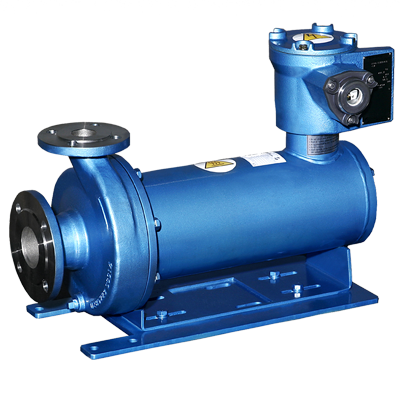

Originating in the English term "canned (goods)", as the name indicates, the structure of a canned motor pump is designed so that the motor coil is enclosed within a can and integrated with the pump. One feature of that structure is that it results in a pump that is completely leak-free, making it applicable for transporting liquids that are explosive, flammable or toxic as well as chemicals like strong acids or strong alkalis. Also characteristic is its excellent durability in high-temperature and high-pressure applications.

Image video of canned motor pump transporting liquid

The difference between a standard pump and a canned motor pump

Standard pumps are produced with the pump and motor located separately and, because they must be coupled for use, the liquid they handle can leak outside the pump from the gaps in the casing through which the rotating axis passes. However, because our canned motor pumps employ a structure in which the pump and motor are integrated and the liquid they transport is sealed inside, it is characterized by being completely leak-free.

STANDARD PUMP

Leaks from the shaft seal.

CANNED MOTOR PUMP

The structure in which the pump and motor are integrated and

the liquid being handled is sealed in makes it leak-free.

The excellent features of a canned motor pump

FEATURE 01 | COMPLETELY LEAK FREE

Since there is no possibility of the pumped liquid leaking out, these pumps are suitable for handling liquid that is harmful to humans, explosive or flammable liquid, expensive liquid, corrosive liquid, etc.

FEATURE 02 | NO CONTACT WITH OPEN AIR

Since no outside air enters the pump, they are suitable for operation in a vacuum, or for handling liquids whose quality changes when exposed to the outside air.

FEATURE 03 | COMPATIBLE WITH A WIDE RANGE OF PRESSURES AND TEMPERATURES

No shaft seal means it is easy to manufacture pumps that can handle systems with high pressure, high-temperature liquids, low-temperature liquids, high melting point liquids, and more.

FEATURE 04 | NO LUBRICATION NEEDED

Because these pumps do not require lubrication oil, there is no contamination of the transported fluid, and the hassles of adding oil is unnecessary.

FEATURE 05 | COMPACT, LIGHTWEIGHT,

AND SPACE-SAVING

Since the motor shaft also serves as the pump shaft, the design is compact, lightweight, requires minimal installation space, and is easy to overhaul.

FEATURE 06 | QUIET OPERATION

Operation noise is minimized because there is no fan to cool the motor.

Canned motor pumps are friendly

to both people and the global environment

Because canned motor pumps have a "completely leak-free" structure, there is no damage or danger from leakage. They thus offer the advantage of eliminating any concern over contamination and environmental pollution and, in this way, serve excellent support to resolving environmental issues as the most people-friendly and environmental-friendly pumps around.

©2024 Teikoku South Asia Pte Ltd | Design by Grafichaus Intermedia.